|

|

Build Your Online Product Catalogs?

| Product Name: |

Primer solution for silicone rubber insulators

|

| Supply Ability: |

10000Tons/Months |

| Related proudcts |

silicone fiberglass, |

| Specifications |

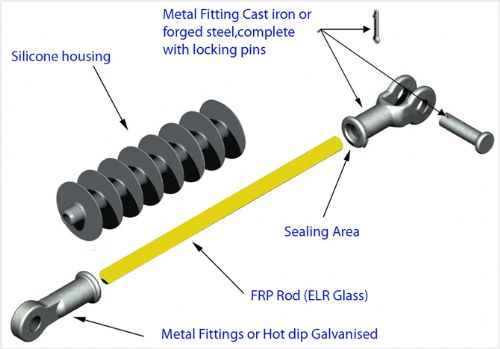

Silicone housing bonding with frp rods |

| Price Term: |

FOB |

| Port of loading: |

Shenzhen Shekou |

| Minimum Order |

5kg |

| Unit Price: |

FOBUSD 28/KG |

|

Silicone Primer CL-24S-2D

(Silicone to Epoxy Bonding)

Products Description

CL-24S-2D, one component silicone primer for Peroxide addition uncured silicone rubber bonds with Epoxy, Carbon metal,such as carbon stainless steel, aluminum, copper, Zn plating and nickle plating materials with excellent adhesion after curing.

Features

ï¬Excellent adhesion for both once curing and second curing peroxide silicone rubber.

ï¬One component, single coating, simple process.

ï¬Resistance for many kind severe rugged environment, such as water resistance, salt fog resistance, chemical resistance, oil resistance, and solvent resistance etc...

ï¬Testing Programme Testing Standard

ï¬Appearanceï¼? Tran***rent Liquid

ï¬Densityï¼?5âï¼ï¼? 0.80g/cm3

ï¬Hazard Classificationï¼? None

ï¬Break down Voltage(Attaching 4mm Silicone sleeveï¼ï¼ 30KV/Cã?

ï¬Temperature Resistanceï¼? -60~180â?

ï¬Shear Strengthï¼? 11KG/ Cã?

Processing

1. Surface treatment: Cleaning the raw material with blast sanding, polishing or washed

by industrial alcohol.

2. Primering on: Brush, dipping or spraying.

3. Curing condition: Curing at 25â?room temperature for at least 30 minutes or baking at 110~130â?for 5-15 minutes.

4. After treatment: The treated substrates should be better to bond a.s.a.p. The max. Storage time can not be exceed 5 days under pollution- free environment.

5. Vulcanizing: The first curing is based on the silicone rubberâs curing condition, the second curing condition can not exceed 200â?

Testing Data

Testing one: Silicone glue to Stainless 45#(In accordance with ASTM D429-B)

Raw material Curing type Result

KE-951U Flat vulcanization, hot air vulcanization cohesive failure

DOW CORNING75 Flat vulcanization, hot air vulcanization cohesive failure

Testing Two: Silicone glue to Epoxy core rod

P |

| Company: |

Shenzhen Kanglibang Science Technology Co.,Ltd

|

| Contact: |

Mr. michael liu |

| Address: |

H building, Xinwei The 3rd Industry Park, DaLang Street, Longhua District, Shenzhen, China. |

| Postcode: |

518109 |

| Tel: |

+86-0755-81478876-8018 |

| Fax: |

+86-0755-81478372 |

| E-mail: |

|

|

|

|